Reloading

Reloading ammunition allows shooters to save money and customize performance. Handloading improves precision and control.

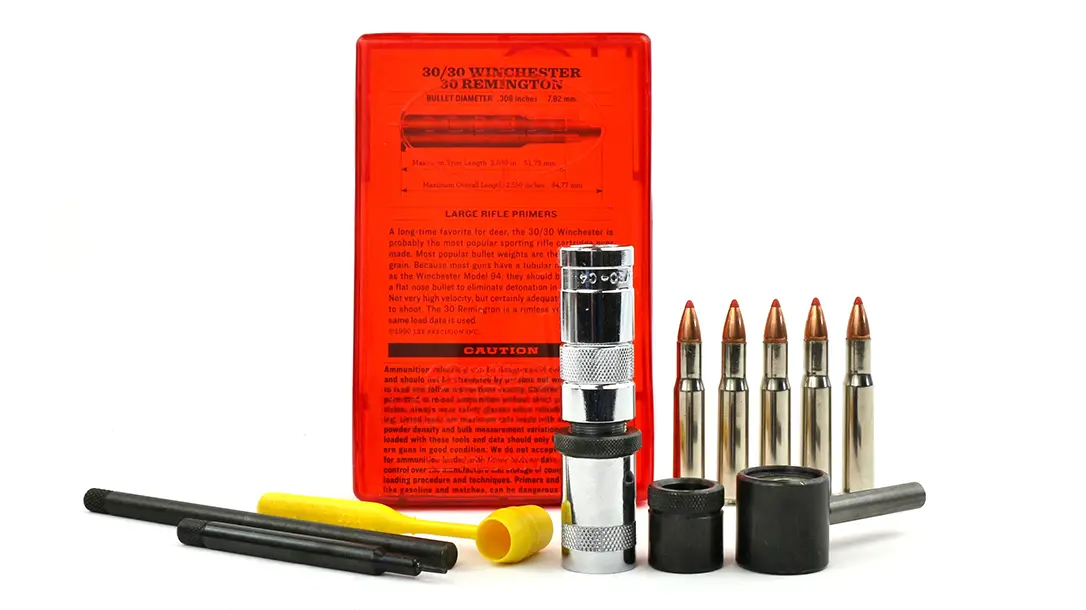

Learn proper safety techniques. Handling powders, primers, and bullets carefully is essential for safe reloading.

Explore different calibers and load types. Each firearm and shooting application has unique requirements.

At Athlon Outdoors, we provide step-by-step reloading guides. Our tutorials cover equipment, techniques, and best practices.

Discover tips for consistent, accurate rounds. Proper measurement, seating, and inspection ensure reliable performance.

Understand the tools of the trade. Presses, dies, and scales help every shooter achieve safe and efficient handloading.

Master reloading to enhance accuracy, reduce costs, and enjoy a more customized shooting experience safely.